CNC Turning and Milling Machine TCK66Y

- Overview

- Related Products

- Product Parameters:

- Details Images

- Packaging & Shipping

- Company Profile

- Certification:

- FAQ:

All machines in our company have multiple colors to choose from, and we support customers to customize exclusive colors!

SPECIFICATIONS |

Units |

TCK66Y-1000/1500 |

Swing over bed |

mm |

660 |

Swing over cross slide |

mm |

400 |

Maximum rod through hole diameter |

mm |

72 |

X axis travel |

mm |

320 |

Zaxis travel |

mm |

1050/1650 |

Y axis travel |

mm |

±55 |

X/Z/Y fast speed |

m/min |

30/30/10 |

X/Z/Y linear guide spec |

mm |

45/45/35(roller guide) |

X/Z/Y axis screw diameter / pitch |

mm |

4210/4012/4010 |

X/Z/Y axis servo-motor torque |

n.m |

12/12/12 |

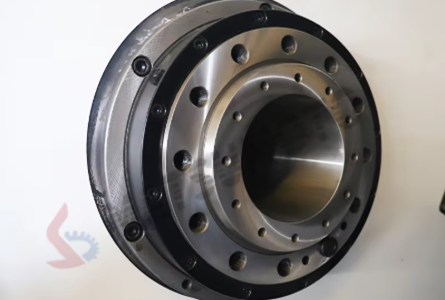

Spindle nose type |

- |

A2-8 |

Spindle bore |

mm |

86 |

Spindle speed range |

rpm |

50-3500 |

Main spindle motor |

kw |

11/15 |

Chuck size |

inch |

10inch |

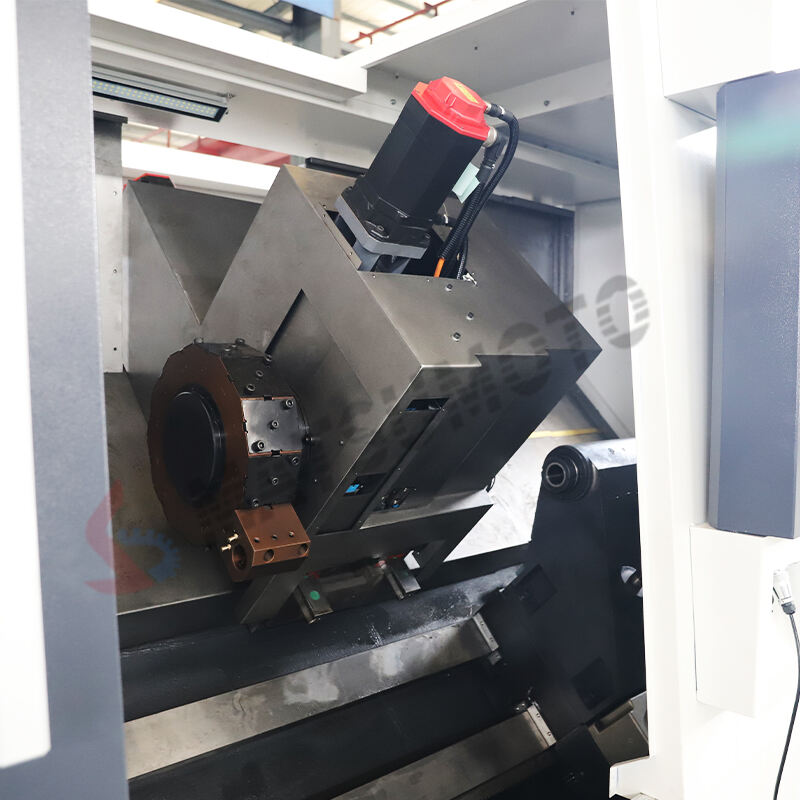

Tools tower |

- |

BMT55/25*25 12 station servo power tower |

Power tools tower motor power |

Kw |

3 |

Power tools tower speed |

r/min |

3000 |

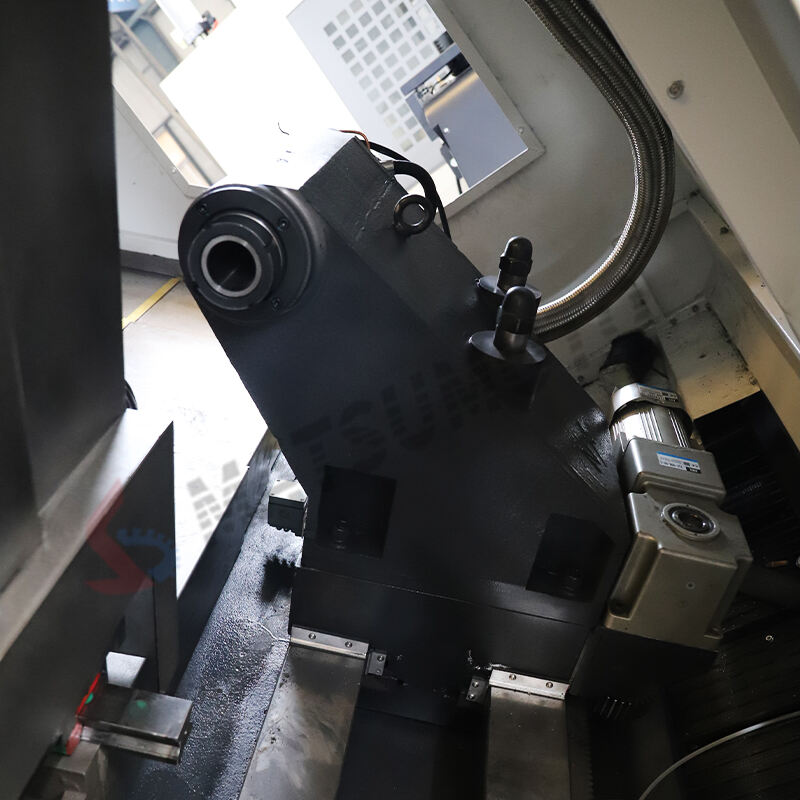

Tailstock taper |

mm |

MT5 |

Max. travel of tailstock |

mm |

100 |

Tailstock diameter |

mm |

80 |

Tailstock form |

- |

Hydraulic |

Machine weight |

kg |

7600 |

Overall dimension |

mm |

4700*1900*2300 |

|

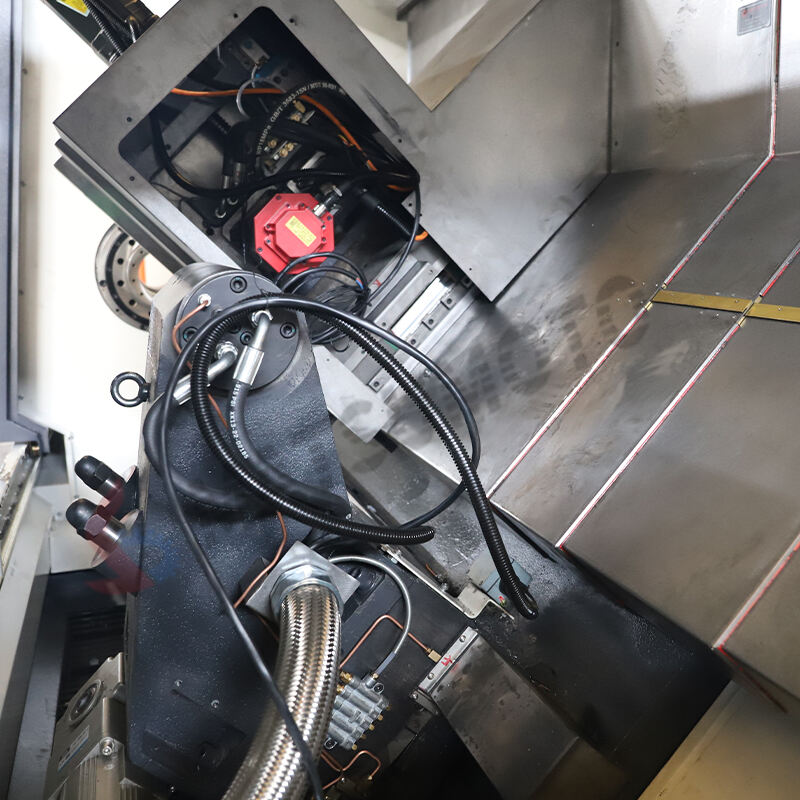

BED CASTING

The key to castings is timeliness, putting quality to first to ensure customer satisfaction. |

|

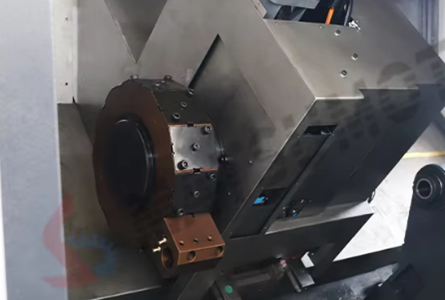

PNEUMATIC CHUCK

Strong clamping during work, long service life. |

|

ROW TOOL POST

High positioning accuracy, stable and reliable, simple structure, convenient maintenance. |

|

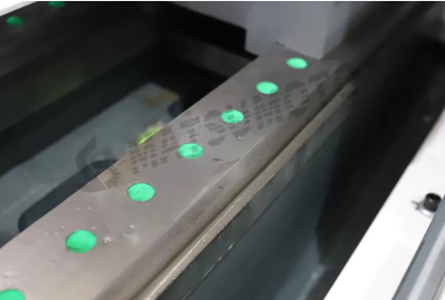

GUIDE

The guide rails are quenched by super audio frequency, and the sliding guide rails are all pasted with wear-resistant plastic. |

|

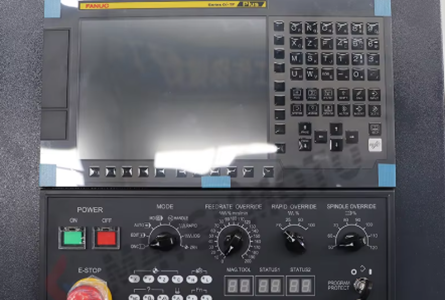

CNC CONTROL SYSTEM

Standard:GSK Optional:SIEMENS/FANUC/MITSUBISHI etc. |

1.Standard plywood case,its compressive strength and bearing quality is better.

2.The board area is bit,the soil structure is good,it is better in leak proofness and waterproof.

3.When importing,the plywood case is with fumigation-free,the procedure is simple.

4.Delivery Detail:within 7-15 days after received your payment.

Shandong Matsumoto Machine Tool Co., Ltd.specializes in the production of processing machine tools. Its main products include precision products such as CNC lathes, surface grinders,milling machines, and vertical machining centers. It has a complete and scientific quality management system. Shandong Matsumoto Machine Tool Co., Ltd. operates with integrity, and its production strength and product quality have been recognized and praised by the industry.It is a comprehensive machine tool manufacturing enterprise integrating CNC machine tool manufacturing and consulting services. The company has a complete R&D and after-sales service team. Welcome to visit, guide and negotiate business with the company.

Main products:

CNC Lathe Machine、CNC Machine Center/Milling Machine、CNC Turning Machine Center、Lathe machine、Grinding Machine、 Milling machine、Band Sawing Machine.

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you choose the exact model .You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as CNC Lathe Machine、CNC Machine Center/Milling Machine、CNC Turning Machine Center、Lathe machine、Grinding Machine、 Milling machine、Band Sawing Machine and so on .

3: What about the quality of the machine?and after-sales service?

A : Our machine warranty period is 3 years,and we provide free technical service.

4. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

5: What's the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight .

6: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )